Wrong cable.

Some electricians, when independently designing a power supply circuit, neglect elementary calculations of the load on the cable.

As a result, it turns out that the cable operates at currents above the maximum allowable. Where does this lead? At a minimum - heating losses, as a maximum - a fire.

And for everything…

It is necessary to ask the customer what electrical appliances he is going to operate, what their power is and where they will stand. If necessary, it is necessary to distribute the load over several groups of cables or use a cable with appropriate characteristics.

More or less experienced electricians know by memory which cable can “hold” which load. But novice electricians should have such a simplified plate for copper cables on hand:

And for aluminum:

Color marking of cable cores.

According to GOST R 50462 - 2009, a certain color marking of core insulation has been adopted. The most common color combination of a three-core cable: brown - phase, blue - zero, yellow (green) - ground.

This marking was invented to facilitate and safety the work of an electrician during the installation of distribution boxes, switchboards, and connection of electrical appliances.

It is sad when electricians neglect this marking.

Years later, another electrician may find himself in a very difficult situation when, while repairing electrical wiring, he finds that the phase is on the yellow wire ... zero on red ... and earth on blue. Well, if he finds it in time ...

It happens that there is no blue or green core in the cable.

Then the labeling will be amended. For example:

Black, white, blue will be connected like this: phase, ground, zero, respectively.

White, green, red - zero, earth, phase.

Connecting a circuit breaker.

Sometimes the following rule is violated: the input wire is connected from above (to a fixed contact), the outgoing wire is from below (to a moving contact).

And worst of all, when the machine is installed "upside down". In an emergency, a person who is not dedicated to this “know-how”, instead of turning off the line, will turn it on. Well, if no one is working at the end of the cable ...

Connecting several wires to the machine.

There are cases when several cables of various sections are “hung” on one machine.

This fact alone is already a gross violation. But! Moreover! By connecting wires of different cross-sections, it can happen that when the terminal is pressed, only the wire with the largest cross-section will be securely clamped, and the little thing will hang out.

And there was another case:

Our company did not have time to complete the work by the deadline. The director subcontracted another electrical installation firm.

The guys did what they were instructed and dumped.

We began to apply voltage to the networks they had installed ... Two phases were missing at the end of one of the lines. On the outgoing machine there is, but not at the end of the cable. We had already begun to open the trays - suddenly the cable was broken somewhere or the clutch was clumsy ...

The foreman, for the safety of work, went to throw away the cable from the machine. Comes laughing...

It turns out that one of the electricians of the subcontractor company removed little insulation from the ends of the wires. When the ends were pressed with terminals, two wires were clamped through the insulation!!! Was it done by accident or on purpose - history is silent.

So ... carefully connect the wires to the machines. Make sure no insulation gets caught in the terminal.

Zero and earth.

In the houses of the old building, two-wire electrical wiring was laid. There is no ground wire. Some craftsmen connect zero and ground contacts directly in the socket.

What is the risk? If zero burns out in the switchboard or substation, there will be life-threatening voltage on the neutral wire. Accordingly, everything that was grounded in this way will begin to “beat with current”.

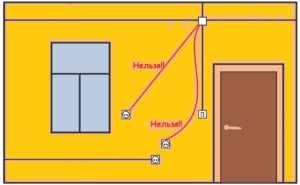

Hidden wiring method.

To save cable and time, some "comrades" lay the wiring at an angle. As a result, years later, when the owner of the apartment decides to drive a nail into the wall, he can get neatly into the wire.

Conclusion: all wires are laid either horizontally or vertically.

Twisting under plaster.

It happens that an electrician lacks a whole piece of cable and he connects it with a twist. The junction is somewhere under the plaster or in the corrugation under the ceiling.

After some time, a poorly made connection oxidizes and the contact disappears at the end of the cable. The electrician who will fix this trouble will have to sweat a lot to find the twist.

But most likely he will turn off the emergency cable, and lay a new one instead - it will be faster and more reliable. His colleague, he will remember with a quiet swear word.

Spare wire.

Whether out of economy, or for some other reason, some electricians leave the short ends of the cable in switchboard, distribution and installation boxes.

When it comes time to connect, the electrician who does this work is not to be envied! The wires are tight! And some ends do not reach the connection point at all. And sho him, tell you to do?