Today I want to show you the work of electricians

In general, an electrician is the most responsible of the construction professions. Their mistakes can lead either to a fire or to the death of ordinary people ... Not in vain, the duration of training for electricians is the longest. And then also annual exams, for confirmation / assignment of a tolerance group + all sorts of special types of training .... All my life I study and pass exams!

A real electrician not only knows how to do it, he understands well what will happen if he does it wrong ... what it will lead to.

The works presented below speak either of the complete ignorance of the performer in their actions, or of elementary laxity, irresponsibility and FSU ... zmu.

So...let's go!!!

I once worked in a team in which a whole dynasty worked: a father and two sons. The father is a real electrician (with a diploma and an admission group), and the sons have never studied anywhere ... right after the army, everything is on the checks, but on the checks. So their father took them to himself, to make electricians out of them. They worked, of course, informally.

At the time when I worked with them, one was 35 and the other 30. They didn’t even think about the length of service or the future pension. Okay, that's their problem. So… in principle, my father made quite smart electricians out of them: laying cables, disconnecting boxes, assembling shields…. were able to do everything. But! So slipshod...

For example, wire stripping. Look at the photo below. In each of their boxes or shields, all the wires had such exposed areas. And how they “didn’t poke their noses” - no reaction. And only when you tell their father: “Ivanych, well, influence your boys! Trouble will do!”

The impact was funny: he would come up to everyone, give generously to his father's slap in the face, cover with obscenities - for several days the guys work perfectly. And then again...

But such twists, during my career as an electrician, I have seen “a wagon and a small cart”. As a rule, an electrician does this when a new wire needs to be brought into an existing junction box.

They can’t think of anything better than winding a strand over a twist. Or they just don't want to bother.

Well, if this wire feeds some kind of light bulb. And if the outlet, which includes a washing machine / boiler?

I saw what this leads to ....

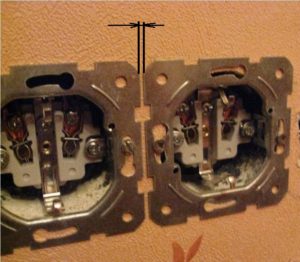

Look at this photo. What do you think? What can lead to such a gap between the strips of the outlet?

These sockets are mounted under one common frame. If there is such a gap, then it will be very problematic to put on a frame. And if there are 4-5 sockets under the frame, then it will be almost impossible.

Bottom line: outlet strips should be close to each other.

The Rules clearly state that each wire must be connected to the ground bus separately.

You can not sculpt a bunch of wires under one bolt!

The electrician must have an understanding of what such installation can lead to.

And the consequences are elementary: if the bolt pressing several tips is not securely tightened, contact with the tire will worsen. One day, one of the consumers has a current leakage ... The current may not go to the bus - the contact is bad. And he will take it, and go along the grounding wires of those consumers who are under the same bolt.

The number of places that will be under dangerous voltage is increasing.

It's so ... one of the options.

And these are my "favorite" twists :)

I once asked the one who connected the “mono-core” with the “washcloth” in this way: “Do you think there will be good contact?”

And he proudly, knowingly answers me: “Well, I bent the wire in the opposite direction! He will press the twist!

Well, what can I say?

And it makes me smile even more when the monofilaments are connected with hooks! Totally a waste!

Rarely, but I met this way of installing a socket or switch.

Let me explain:

So that the socket does not loosen over time and does not fall out of the installation box, it is “sit down” on alabaster! Fill the entire space of the installation box with alabaster and press it into the solution. Even the "antennae" do not unclench! What about the meaning? Alabaster won't let her move!

However, none of those who do this think about the fact that alabaster can draw moisture ... And then the whole wall will be shocked! And if aluminum wires are connected, they simply turn into powder in 3-4 years.

Maintenance of such an outlet, of course, is out of the question!

But this is just a sabotage!!!

Some electricians do "grounding" this way. This action is called zeroing.

As long as the zero in the TP is really reliably connected to the ground loop, this circuit will still somehow protect. But as soon as either zero burns out, or the contact worsens, or in a dry summer, the resistance of the ground electrode will increase ...

In short, at one point, electrical appliances grounded in this way will begin to beat with current so much that you can see Elon Musk's satellites during the day!

And again about grounding...

Nothing to comment here :)

Somehow this guy didn't work...

As I understand it, in addition to the fact that everything is crooked / oblique, they also installed the middle socket so that the contacts are located not horizontally, but vertically!

How did the customer accept such work? Although ... I probably did it for myself :)