A screwdriver bit is not something particularly valuable, expensive. When it falls into disrepair, most craftsmen do not bother about its restoration. Bought a new one and keep working.

However, circumstances can turn so that work needs to be done, and the store is either far away or no longer working ...

When the slots of the bit are worn out, licked off in the area of the tip, the process of screwing in the screws becomes a real torture (both for a person and for a power tool).

So... It's worth knowing a simple way to recover a bit.

First a little theory...

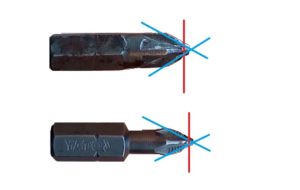

In accordance with the diagram below, cut off 1-2 mm of the tip of the bit (depending on the shape and degree of wear). In the diagram, the cut line is indicated by a red line.

Now you need to grind off the edges indicated by the blue lines.

For PH bits, the angle between these faces is 55 degrees, for PZ bits it is 50 degrees. The value of these angles must be preserved when processing the edges, otherwise the bit will scroll in the slots of the self-tapping screw.

The appearance of the restored bit will be something like this:

How to restore a beat. The easy way.

The practical part of the recovery technology is as simple as its theoretical part.

To grind off the worn tip of the bit, you can use the "grinder", or you can ... without removing the bit from the cartridge, use a file.

Firmly fix the screwdriver (either in a vice, or ask someone to press it against the table and press the start button).

Turn on the screwdriver, place the file, as in the diagram below. To make things go faster, do not hold the file still. Make them back and forth movements.

After processing the tip of the bit, place the file parallel to the outer working edges of the bit.

Maintaining the angle will not be easy. Therefore, first try on the file to the edges with the screwdriver turned off. Then give a command to your assistant to turn on the screwdriver (while you are holding the file at the same angle). Press the file against the edges to be machined.

As soon as the platform of the tip becomes the desired size, the work on restoring the bit is considered completed.

The restored bat can still work. At least until a convenient moment of buying a new bit.