Many, many years ago, when the author of this article studied at a technical university, he had one strange teacher ... in metallurgy. Somehow, at the end of the school year, he asked us such a riddle: “Whoever hardens an ordinary nail (from a hundred or more), he will immediately put an A for the year and you don’t have to come to the exam ...”

Tempting, agree. However… low-carbon steel St1, St2, St3., from which the nail is made… well, it won’t allow this trick to be carried out. However, none of us then got a free five. Because they took the question too literally.

It will not work to harden, but why not cement the surface layer of steel with carbon ???

The file test would have passed with a bang.

There are a lot of videos on YouTube, with the title "How to harden a knife (nail) in graphite." In fact, the technologies described in the videos cannot be called HARDENING. It is rather cementation ... at home.

To solve any household problems - the most IT.

So, if you are still not familiar with this procedure, this article is for you!

You will need:

- Welding machine

- Graphite in powder form (you will have to ruin a few graphite brushes or disassemble old batteries to remove the graphite rod from them from the positive contact)

- Sheet of metal (as a substrate)

- A product that needs strength of character :)

Connect the "MASS" of the welding machine to the sheet of metal on which you place the graphite powder.

Connect the “product” to the holder. Turn on the device.

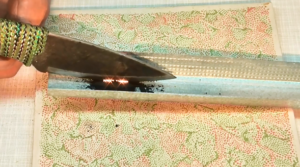

The technology consists in briefly lowering the surface of the “product” into a pile of powder.

Be careful! Do not touch the “product” to the sheet of metal, otherwise a full-fledged arc will occur and your product will burn at the point of contact.

At the point of contact with the powder, you can observe a slight arc. This is fine. This procedure must be performed within 3-5 minutes. Do not expect that the penetration depth of graphite will be more than 0.05 mm. However, this is enough for the blade of a knife or the point of a nail to acquire considerable hardness.

As a test, you can subject the "product" to the following tests:

- the nail firmly resists the impact of the file

- the blade of a knife, like a chisel, interrupts an ordinary nail.

At the same time, there are no significant deformations on the treated surface.

Why do you need all this? Decide for yourself. Hard nails may not be needed, but a knife that does not require frequent sharpening is the very thing.

You can see more details in this video: